Q&A

Mechanical springs are utilized to store kinetic energy to close a valve or a damper every time to ensure failsafe operation in time of emergency without relying on batteries or other external power supplies.

●Duty Cycle

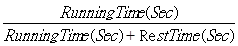

The duty cycle is the relationship between the running time and resting time. It is calculated as below:

Duty Cycle= Ï100%

Ï100%

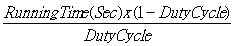

→Rest Time (Sec)=

◎ If the running time for OM-2 is 15 sec, 30% duty cycle, the rest (off) time shall be calculated as below:

-> 15 x 【(1-30%) / 30%】= 35 The rest time will be 35 sec.

◎ If the running time for OM-2 is 15 sec, 75% duty cycle, the rest (off) time shall be calculated as below:

-> 15 x

【(1-75%) / 75%】= 5 The rest time will be 5 sec.

Note: For higher duty cycles, choose the 75% duty cycle.

※ One cycle consists of open-rest-close-rest.

The actuator shall be sized to ensure that its torque output meets the load requirements of valve and its ability to overcome the required duty cycle of application valve (As a MINIMUM, a 30% safety factor is suggested for the calculation of torque requirement).

● If the maximum torque of 5” valve is 80 N‧m 80 × 1.3 (safety factor) = 104 N‧m

● If the maximum torque of 5” valve is 80 N‧m 80 × 1.3 (safety factor) = 104 N‧m

104 N‧m < 150N‧m (OM -3) → OK! OK!

104 N‧m > 90 N‧m (OM -2) → Not OK !

In cases where the actuator does not fit directly onto valve, a mounting kit is required. Please ensure the bracket and coupling are properly designed and manufactured to withstand the torque output of actuator.

In cases where the actuator does not fit directly onto valve, a mounting kit is required. Please ensure the bracket and coupling are properly designed and manufactured to withstand the torque output of actuator.

An Electric Valve Actuator means that the actuator uses electricity as an energy source in a control system.

The electric control valve actuator receives an electric signal such as an adjustment meter, and changes the manipulation amount according to the magnitude of the signal. So that the amount or energy of the input or output control object is changed, and the automatic adjustment purpose is achieved.

In industrial production, electric control valves are the most widely used. The electric regulating valve is composed of two parts: an actuator and an adjusting mechanism (valve).

The electric control valve actuator receives an electric signal such as an adjustment meter, and changes the manipulation amount according to the magnitude of the signal. So that the amount or energy of the input or output control object is changed, and the automatic adjustment purpose is achieved.

In industrial production, electric control valves are the most widely used. The electric regulating valve is composed of two parts: an actuator and an adjusting mechanism (valve).

Each electric valve actuator enclosure has a rating or meets specific standards. The NEMA(National Electrical Manufacturer’s Association) prepares standards which define the actuator with operating and service conditions, reference to construction and material composition and performance and quality etc.

For non-hazardous locations, it is best to use a 4X rating. For hazardous locations, grades 7 and 9 rating are required. The IEC(International Electrotechnical Commission) seal code is similar to the NEMA standard. The IP rating specifies the level of protection against dust and liquid ingress. IP67 is often a level that is easily achieved in most commercial and industrial applications.

Electric Valve Actuator applied to industrial technology, irrigation, water treatment, HVAC, chemicals, food processing, mining, tunnel/metro ventilation, smoke extraction, food industry, environmental protection system, and so on.

Hot Series of Electric Valve Actuator :

Quarter-Turn Electric Valve Actuator : OM series

Spring Return Electric Valve Actuator : S series

Electric Linear Actuator : L series

Explosion Proof Electric Actuator : OME series

Spring Return Electric Valve Actuator : S series

Electric Linear Actuator : L series

Explosion Proof Electric Actuator : OME series

Our electric valve actuators fall into 8 types :

1. OM series : quarter-turn electric actuators

Model OM-1 to OM-13 and other BM-2, OM-A, OM-AM quarter-turn electric actuators. Provide torque ranges from 35N‧m to 4500N‧m. The most distinctive design is clutch-less manual override (except BM-2 and OM-A).

2. S series : spring return fail-safe electric actuators

Model S-500, S-1300, S-2000 and S-2600 spring return fail-safe electric actuators. Provide torque ranges from 50N‧m to 260N‧m. In addition to standard open/close (two-position) control, floating and modulating control are available for option per application requirements.

3. L series : linear electric actuators

Model L-250, L-500, L-1000 and L-2000 linear electric actuators. Provide thrust force ranges from 250 to 2000 kgf. Standard with modulating control fits with globe valves and other linear motion devices.

4. T series : compact quarter-turn electric actuators

Model T-6 and T-15 compact quarter-turn electric actuators. Provide torque ranges from 6N‧m and 15N‧m. Designed for small space and it is still standard with NEMA 4X/5 enclosure and ISO 5211 mounting flange.

5. CM series : part turn electric valve actuators

Model CM-100 to CM-600 part turn electric valve actuators. Provide torque ranges from 100N‧m to 600N‧m. Fits with butterfly valves, plug valves, ball valves, etc. Standard with open/close control and modulating control is optional.

6. OME series : explosion-proof quarter-turn electric actuators

Model OME-1 to OME-8, OME-A and OME-AM explosion-proof quarter-turn electric actuators. Provide torque ranges from 35 N‧m to 1500N‧m. The manual override can be operated without clutch and brake and structured as flame-proof & combustible dust-proof.

7. SE series : explosion-proof spring return fail-safe electric actuators

Model SE-500, SE-1300, SE-2000 and SE-2600 explosion-proof spring return fail-safe electric actuators. Structured as flame-proof and combustible dust-proof. Designed to provide fail-safe positioning of valves and dampers upon loss of voltage supply.

8. LE series : explosion-proof linear electric actuators

Model LE-250, LE-500, LE-1000 and LE-2000 explosion-proof linear electric actuators. Provide thrust ranges of 250kgf to 2000 kgf. All models structured as flame-proof and combustible dust-proof. Equipped with modulating controllers and are suitable for globe valves, gate valves and linear travel devices.

If you are interested in electric valve actuators, please feel free to contact us!

If you are interested in electric valve actuators, please feel free to contact us!