SEMICONDUCTOR MANUFACTURING PROCESS

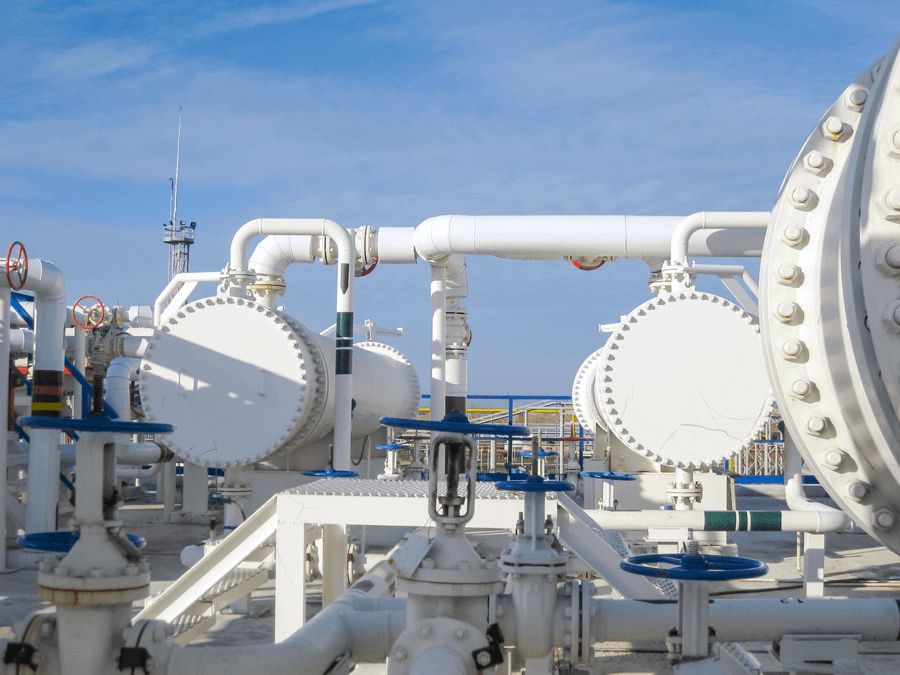

Semiconductor fabrication requires ultra-clean, tightly controlled environments. As process nodes shrink and yield targets rise, precision in fluid and airflow control becomes mission-critical.

INDUSTRY PAIN POINTS

- Stringent Process Requirements: Semiconductor manufacturing demands extremely high standards for environmental cleanliness and stability. Even minor deviations in temperature or pressure can impact product yield and result in significant losses.

- Limited Equipment Selection: Cleanroom environments impose strict requirements on material compatibility and emissions. Many conventional devices fail to meet these standards, restricting system design flexibility and equipment choices.

- Corrosive Media Challenges: Highly corrosive fluids are common in chemical and ultra-pure water (UPW) systems, placing greater demands on actuator materials and sealing integrity. Improper selection can lead to frequent failures.

- Insufficient Response Speed: Some actuators respond too slowly to keep up with dynamic process changes, compromising control accuracy and overall process stability.

- High-Cycle Operational Stress: Semiconductor equipment operates continuously at high frequencies, placing heavy demands on actuator durability and reliability. Inadequate performance can negatively affect overall production capacity.

SOLUTIONS

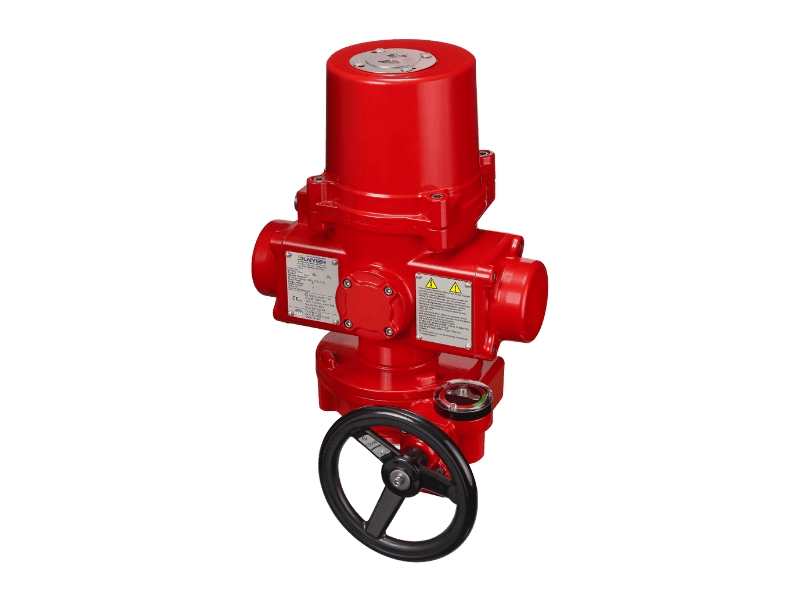

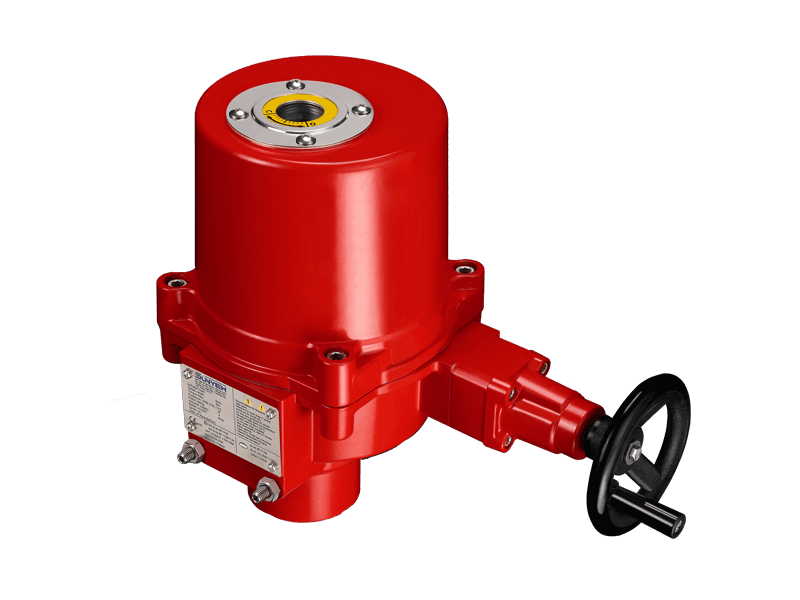

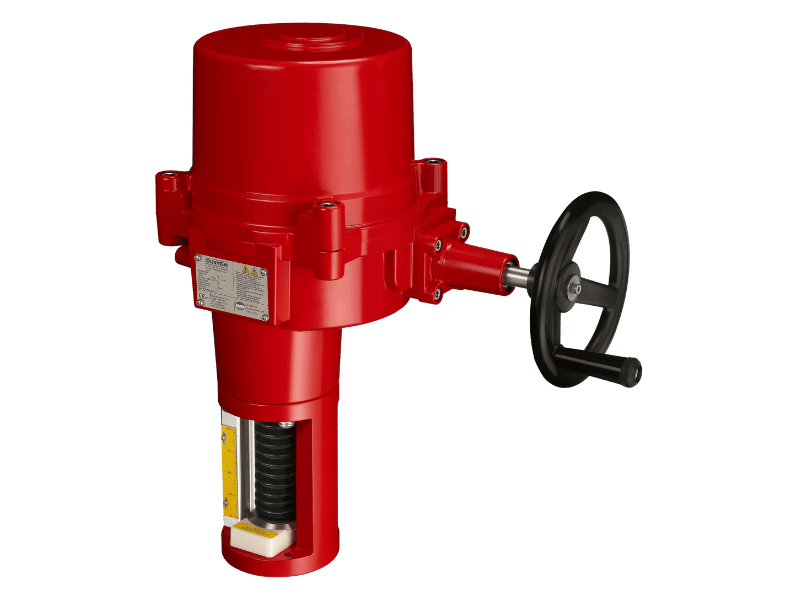

Sun Yeh electric actuators are ideally suited for precision control of critical fluids and gases in semiconductor manufacturing environments, including cleanroom HVAC systems, ultra-pure water networks, and chemical delivery pipelines. With high-accuracy modulation and corrosion-resistant construction, they deliver stable performance under high-cycle, high-purity conditions. Fast response times enhance process consistency and yield, while remote monitoring and modular integration minimize maintenance requirements and reduce labor dependency, enabling enterprises to maintain efficient, low-risk process operations.