Blog

2026-01-16

Blog

Why Hazardous Location Linear Electric Actuators Need Specialized Design in High-Humidity and Dusty Industrial Environments

In high-humidity, dusty, or corrosive environments such as chemical plants, petrochemical facilities, wastewater treatment systems, mining operations, and powder-processing lines, a standard linear electric actuator is not sufficient. Safety regulations, environmental durability, and long-term reliability must all be considered simultaneously. However, when these actuators operate in hazardous locations—where flammable gases, vapors, or combustible dust may be present—the design requirements become significantly more complex.

As a specialist in electric actuators and explosion-proof actuation technology, Sun Yeh Electrical Ind. Co., Ltd. designs hazardous-location linear electric actuators that meet international explosion-proof standards while maintaining precise control performance. This article explores the key engineering considerations behind these actuators and explains how proper design ensures safety, stability, and long service life in extreme environments.

2026-01-09

Blog

What Do Explosion-Proof Standards Mean? Ensuring Safety in Hazardous Zones

In industries where flammable gases, vapors, or combustible dust are present, safety is not a checklist item—it is a system-level responsibility. Petrochemical plants, natural gas facilities, chemical processing lines, and powder-handling operations all operate under conditions where a single ignition source can lead to catastrophic consequences.

As a professional manufacturer specializing in electric actuators and explosion-proof electric actuators, Sun Yeh Electrical Ind. Co., Ltd. works closely with engineers, EPC contractors, and plant operators worldwide. Beyond supplying certified products, Sun Yeh is committed to helping customers understand explosion-proof standards correctly, ensuring that actuator selection is based on engineering principles—not assumptions. This article aims to clarify explosion-proof markings, hazardous area classifications, and certification systems, empowering decision-makers to design safer and more reliable systems.

2025-12-24

Blog

Smart Valve Automation in Industry 4.0: The Future of Electric Actuation

As global industries accelerate toward digital transformation, Industry 4.0 has become the defining trend across manufacturing, utilities, energy, and environmental systems. In this new industrial era, automation is no longer limited to basic open-close control. Instead, factories require smart, data-driven valve actuation systems capable of continuous monitoring, remote adjustments, predictive maintenance, and seamless integration with centralized SCADA and IoT platforms.

Among all actuation technologies, the electric actuator has emerged as a core component for building smarter and more connected flow-control environments. In this article, we explore how smart electric actuators support Industry 4.0, which features matter most, and how they improve efficiency across key sectors such as water treatment, energy plants, HVAC, and industrial processing.

2025-11-05

Blog

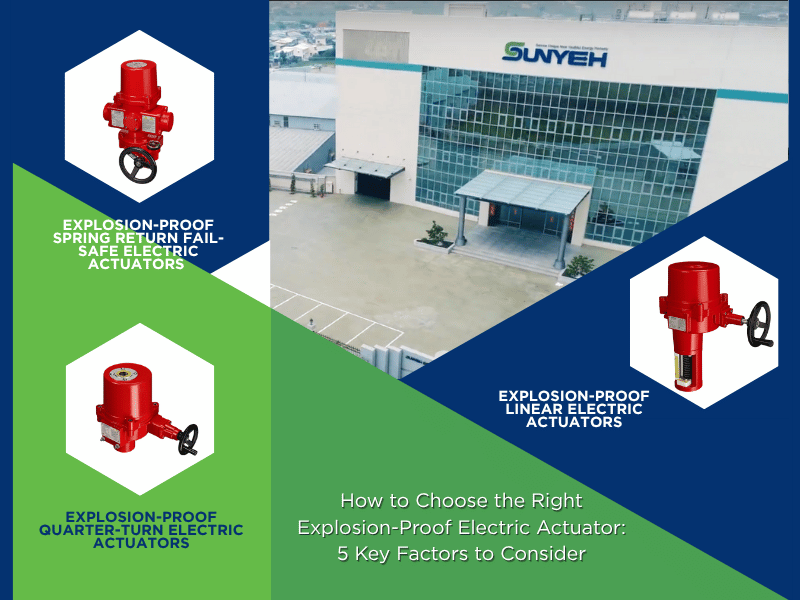

How to Choose the Right Explosion-Proof Electric Actuator: 5 Key Factors to Consider

Selecting the right one requires careful consideration of multiple technical and safety factors. Beyond torque and mounting size, you need to ensure the actuator's certification, construction, and control system align with your operational environment. To help guide your selection, here are the five key factors to consider when choosing an explosion-proof electric actuator.

2025-10-08

Blog

What is an Electric Actuator? A Complete Guide to Principles, Types, and Applications

In today’s world of industrial automation and fluid control, electric actuators play an essential role. They convert electrical energy into mechanical motion to control valves, dampers, and other equipment automatically. From petrochemical plants and water treatment systems to HVAC and building automation, electric actuators ensure precision, efficiency, and reliability across countless applications.

This article explores how electric actuators work, their major types, and where they’re most commonly used — helping you understand why they’ve become indispensable in modern industry.