よくある質問

機械的なスプリングに貯めた反発力によりバルブやダンパーを遮断することで、緊急時にフェイルセーフ機能を果たし、外部の電源ユニットやバッテリーが不要です。

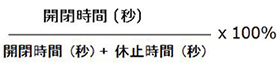

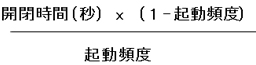

下記はIEC規格に基づいた起動頻度の計算式です。

起動頻度=

→休止時間 (秒) =

● 例:OM-2の開閉時間は15 秒、起動頻度30% duty cycleの場合

[ 15 × (1 - 30 %) ] / 30 % = 35、休止時間 35 秒が必要。

● 例:OM-2の開閉時間は 15秒、起動頻度75% duty cycleの場合

[ 15 × (1 - 75 %) ] / 75 % =5、休止時間 5 秒が必要。

*過負荷を防止するため、起動頻度の高い場合、起動頻度75% duty cycleの仕様をお選びください。

*1サイクル=0°~ 90°の開閉時間 + 休止時間 + 90°~ 0°開閉時間 + 休止時間。

安全係数を掛けたバルブのトルク値はアクチュエータの最大トルク値以下であることをご確認ください。(推奨安全係数:1.3)

l 125Aバルブのトルク値が80N.mの場合 → 80 × 1.3=104 N.m

104 N.m < 150 N.m (OM-3) →取付け可能

104 N.m > 90 N.m (OM-2) →取付け不可

バルブの弁棒寸法及び取付フランジがアクチュエータとの一致していることをご確認ください。一致しない場合、アダプターやブラケットを利用して取付けてください。

An Electric Valve Actuator means that the actuator uses electricity as an energy source in a control system. The electric control valve actuator receives an electric signal such as an adjustment meter, and changes the manipulation amount according to the magnitude of the signal. So that the amount or energy of the input or output control object is changed, and the automatic adjustment purpose is achieved.

In industrial production, electric control valves are the most widely used. The electric regulating valve is composed of two parts: an actuator and an adjusting mechanism (valve).

Each electric valve actuator enclosure has a rating or meets specific standards. The NEMA(National Electrical Manufacturer’s Association) prepares standards which define the actuator with operating and service conditions, reference to construction and material composition and performance and quality etc.

For non-hazardous locations, it is best to use a 4X rating. For hazardous locations, grades 7 and 9 rating are required. The IEC(International Electrotechnical Commission) seal code is similar to the NEMA standard. The IP rating specifies the level of protection against dust and liquid ingress. IP67 is often a level that is easily achieved in most commercial and industrial applications.

Electric Valve Actuator applied to industrial technology, irrigation, water treatment, HVAC, chemicals, food processing, mining, tunnel/metro ventilation, smoke extraction, food industry, environmental protection system, and so on.

The hot types of electric valve actuator series :

- Quarter-Turn Electric Valve Actuator : OM series

- Spring Return Electric Valve Actuator : S series

- Electric Linear Actuator : L series

- Explosion Proof Electric Actuator : OME series

Under Construction